PRODUCTS

COLD ROLLED PRODUCTS

The cold-rolled strips supplied by the company are tailor-made for individual customers. Each product is manufactured exactly as per the customers’ specifications, requirements and expectations. Therefore, for each order of all the customers, a product-specific process route is designed first, which consists of the detailing of every process, the selection of raw material grade and size, the intermediate thicknesses to be rolled, the intermediate annealing to be carried out, etc. Throughout the processing of the customers’ orders, the process route is followed to ensure that the material is produced exactly as per the customers’ specifications.

We cater to your small needs

with large expectations

FACILITY AND PROCESS

Cold Rolling Process

Manufacturing of cold-rolled strips:

The key plant facilities include a state-of-the-art 4Hi cold rolling mill, two 20Hi Sendzimir cold rolling mills and a modern hydrogen annealing setup. The combination of these manufacturing facilities enables the company to cater to a very large range of cold-rolled products in a thickness range of 0.050 mm to 4.0 mm in a variety of steelgrades.

TYPES OF PRODUCTS

1. Mild Steel Grades

| Category | Steel Grade | Chemical Composition (%) | Nearest Equivalent Specifications | |||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | S Max | P Max | Si | Cr | |||

| Mild Steels | D | 0.12 Max | 0.50 Max | 0.040 | 0.040 | Traces | DC 01 DIN EN 10139 |

|

| AISI 1010 | 0.08 - 0.13 | 0.30 - 0.50 | 0.040 | 0.040 | Traces | C 10 E DIN EN 10132-2 |

||

| DD | 0.10 Max | 0.45 Max | 0.040 | 0.040 | Traces | DC 03 DIN EN 10139 |

||

| EDD | 0.080 Max | 0.30 Max | 0.025 | 0.025 | Traces | N: 0.007 Max, Al: 0.02 - 0.07 | DC 04 DIN EN 10139 |

|

Note:

- In the MS grades, there may be the presence of residual or tramp elements (such as Cr, Ni, Cu, Mo, etc.) up to 0.20% and Al up to 0.07%.

- Besides the above, other grades in the mild steel category can also be supplied depending on the order quantity and availability of appropriate raw materials.

Mild Steel Capability:

| Capability | |

| Mild Steels | |

| Width: 6mm - 450mm Thickness: 0.076mm - 3.5mm |

Coil ID 150 / 300 / 400 / 450 / 500 mm depending on width and thickness Sp. Coil wt. 050 to 7kg per mm width depending on width and thickness |

| Surface Finish: Matt finish option for annealed and skin passed material | |

2. Medium Carbon Steel

| Category | Steel Grade | Chemical Composition (%) | Nearest Equivalent Specifications | |||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | S Max | P Max | Si | Cr | |||

| Medium Carbon Steel | C 40 | 0.35 - 0.45 | 0.50 - 0.90 | 0.040 | 0.040 | 0.35 Max | C 40 E DIN EN 10132-3 |

|

| C 45 | 0.42 - 0.48 | 0.60 - 0.90 | 0.040 | 0.040 | 0.35 Max | C 45 E DIN EN 10132-3 |

||

| C 55 | 0.50 - 0.60 | 0.60 - 0.90 | 0.040 | 0.040 | 0.35 Max | C 55 E DIN EN 10132-3 |

||

| C 62 | 0.60 - 0.67 | 0.50 - 0.90 | 0.035 | 0.035 | 0.35 Max | C 60 E DIN EN 10132-3 |

||

Note:

- In the MC and HC grades, the percentage of Si and Al will depend on the deoxidation practices adopted by the steel makers.

- In MC and HC grades, residual or tramp elements (such as Cr, Ni, Cu, Mo, etc.) may be present depending on the steel-making practices followed by the steel makers.

- Besides the above, other grades in this category can also be supplied depending on the order quantity and availability of appropriate raw materials.

Medium Carbon Steel Capability:

| Capability | |

| Medium Carbon Steels | |

| Width: 6mm - 350mm Thickness: 0.10mm - 3.0mm |

Coil ID 150 / 300 / 400 / 450 / 500 mm depending on width and thickness Sp. Coil wt. 050 to 6kg per mm width depending on width and thickness |

3. High Carbon Steel

| Category | Steel Grade | Chemical Composition (%) | Nearest Equivalent Specifications | |||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | S Max | P Max | Si | Cr | |||

| High Carbon Steel | C 75 | 0.70 - 0.80 | 0.60 - 0.85 | 0.030 | 0.030 | 0.35 Max | C 85 S DIN EN 10132-4 |

|

| C 80 | 0.75 - 0.85 | 0.50 - 0.90 | 0.040 | 0.040 | 0.35 Max | C 75 S DIN EN 10132-4 |

||

| C 98 | 0.90 - 1.05 | 0.30 - 0.60 | 0.040 | 0.040 | 0.10-0.35 | C 100 S DIN EN 10132-4 |

||

Note:

- In the MC and HC grades, the percentage of Si and Al will depend on the deoxidation practices adopted by the steel makers

- In MC and HC grades, residual or tramp elements (such as Cr, Ni, Cu, Mo, etc.) may be present depending on the steel-making practices followed by the steel makers.

- Besides the above, other grades in this category can also be supplied depending on the order quantity and availability of appropriate raw materials.

High Carbon Steel Capability:

| Capability | |

| Medium Carbon Steels | |

| Width: 6mm - 400mm Thickness: 0.10mm - 3.0mm |

Coil ID 150 / 300 / 400 / 450 / 500 mm depending on width and thickness Sp. Coil wt. 050 to 6kg per mm width depending on width and thickness |

4. Low Alloy Steel

| Category | Steel Grade | Chemical Composition (%) | Nearest Equivalent Specifications | |||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | S Max | P Max | Si | Cr | |||

| Low Alloy Steel | 50 Cr V4 | 0.47 - 0.55 | 0.70 - 1.10 | 0.035 | 0.035 | 0.15 - 0.40 | 0.90 - 1.20 | C 85 S DIN EN 10132-4 |

| 125 CR 1 | 1.10 - 1.30 | 0.25 - 0.60 | 0.030 | 0.035 | 0.35 Max | 0.20 - 0.50 | C 75 S DIN EN 10132-4 |

|

Notes:

- In these grades, the percentage of Si and Al will depend on the deoxidation practices adopted by the steelmakers

- In these grades, residual or tramp elements (such as Cr, Ni, Cu, Mo, etc.) may be present depending on the steel-making practices followed by the steel makers.

- Besides the above, other grades in this category can also be supplied depending on the order quantity and availability of appropriate raw materials.

Low Alloy Capability:

| Capability | |

| Medium Carbon Steels | |

| Width: 6mm - 400mm Thickness: 0.10mm - 3.0mm |

Coil ID 150 / 300 / 400 / 450 / 500 mm depending on width and thickness Sp. Coil wt. 050 to 6kg per mm width depending on width and thickness |

TYPICAL APPLICATIONS

Mild Steels: Auto industry (pressed and deep drawn parts), electronic industry, containers, retainers, and cages for ball and needle roller bearings, textile machinery, flashlight parts, battery caps, shims, and gaskets, and containers for the paint industry.

Medium Carbon Steels: Auto industry (motorcycle chains, springs), industrial chains, general engineering industry, rifle and gun parts, hair pins, measuring tapes.

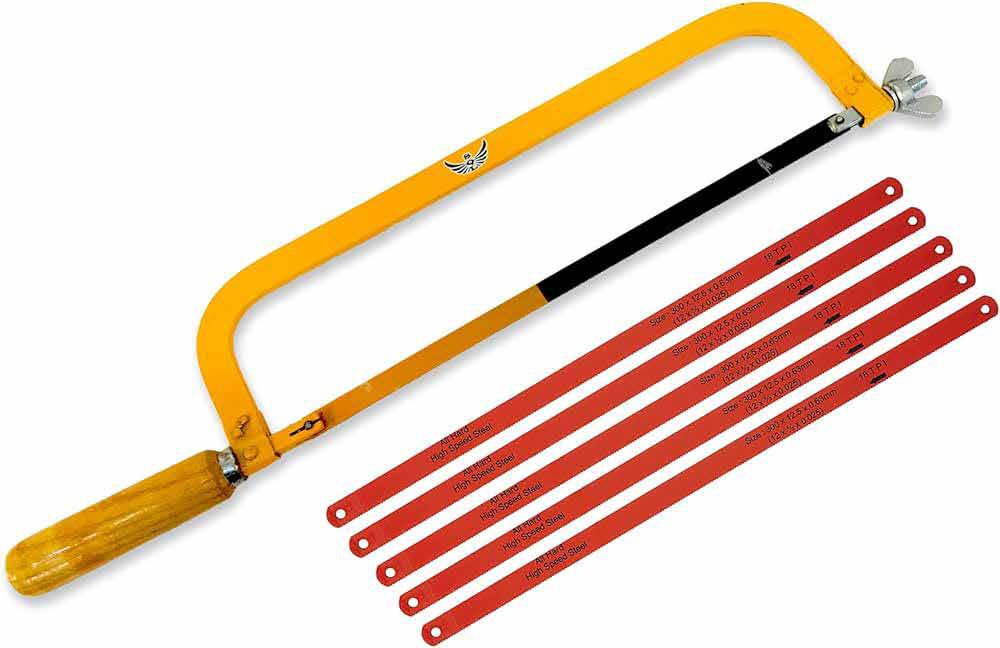

High Carbon Steels: Auto industry (clutch parts, circlips/retainer rings, springs, horn diaphragm, etc.), textile m/c components (drop wire pins, healds), circular saws, hand hacksaw blades, general engineering (spring washers, dowel pins, etc.)

Low Alloy Steels: Metal cutting band saws and hand hacksaw blades, surgical blades, pencil sharpener blades and knitting

needles.