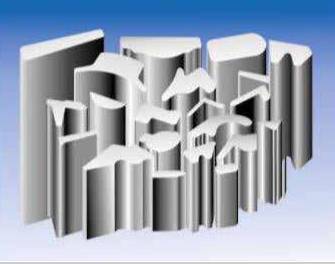

PROFILES

The Profiles division has a state-of-the-art manufacturing facility for producingcustom-made hot-rolled profiles, cold-drawn profiles and pre-shaped profiles for cold-drawing.

Hot-rolled profiles are solid shapes or sections that are manufactured from either billets or wire rods. Unlike extrusion, where molten metal is pushed through a dye to obtain the required shape, the hot rolling process involves shaping the heated billets or wire rods by passing through a set of rolling stands. Each roll set has a specific pass design. These profiles or sections have the same shape or cross-section throughout the length, i.e., they are two-dimensional shapes.

- Sections have better dimensional tolerances and consistency due to continuity in rolling.

- Sections have a better surface finish due to low scaling.

- The minimum order quantity can be as low as 5 MT per section.

| Steel Grades | |

| Mild Steels & Low Carbon High Strength Steels | SAE 1008, SAE 1010, ST 37.2, C-15, C 15 Pb Fe 540 B |

| Medium Carbon Steels | S45C, C 50, C 55, C 60, St 70.2 |

| High Carbon Steels | C 75 S, C 80 |

| Alloy Steels | File Steels etc. |

| Size Capability | |

| Thickness | 3.0 mm Minimum |

| Width | 8.0 mm to 45 mm |

| Cross-Sectional Area | 490 Sq. mm in general, however, profile sections having cross-sectional areas up to 525 Sq. mm may also be produced depending on shape |

| Specific Weight | In straight length, 0.20 - 4.50 Kg per meter & 3000 mm to 11000 mm. In coils, Sp. Wt. of 1.30 Kg. per meter & ID of 750 mm and coil weight of 400 Kg. max./td> |

| Tolerances | |

| On Thickness | +/- 0.2 to +/- 0.5 mm |

| On Width | +/- 0.2 to +/- 0.5 mm |

| On Length | + 100 mm, -0 mm |

FACILITY AND PROCESS

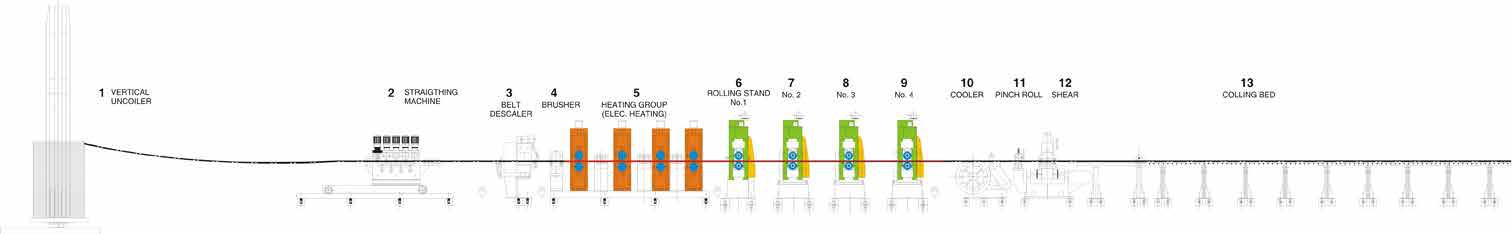

Profiles Hot Rolling Process

The Profiles division has a state-of-the-art manufacturing facility for producing 6,000 MT per annum of intricate custom-made hot-rolled solid steel sections with close dimensional tolerances. The profile plant, which is the only plant of its kind in India, consists of a world-class profile hot rolling mill and an in-house tool manufacturing facility.

The uniqueness of this latest technology lies in the fact that the profiles are rolled from wire rods that are continuously heated online with electrical resistance heaters, unlike billets that are heated in fuel-fired furnaces in conventional rolling mills.

Advantages over Conventional Rolling

- Reduced scaling on account of electrical heating.

- Better dimensional tolerances due to reduced scaling.

- Consistency in dimensions is due to continuous rolling.

- Minimised material waste on account of better tolerances

- Reduced cost of machining operations and saving time.

Profile Process

The custom-made solid profiles and sections in various grades of steel are manufactured using state-of-the-art technology through a hot rolling process. The profile sections are rolled from wire rods, which are electrically heated on a continuous line, unlike conventional billet rolling. The profile sections rolled by us have superiority over the sections conventionally rolled from billets for dimensional tolerances and surface quality.

TYPES OF PROFILES

1. Agricultural

We are the pioneers in the manufacture of hot-rolled sections for various agricultural implements, such as sickles and coffee choppers. Sickles are used for harvesting as well as weeding or grass-cutting operations and have conventionally been manufactured by the village smiths.

The sickles made from specially produced tapered profile sections have a distinct edge over the conventionally hand-made sickles, as can be seen from the following comparison:

| Conventional Handmade Sickles | Sickles Made from Profile Sections |

| The quality of steel is not guaranteed as these are made from scrap, which does not give consistency in heat treatment. Hence, final quality is not guaranteed. | A special grade of medium-carbon steel is used to make profile sections, which gives consistency in heat treatment and hence guarantees the final quality. The hot-rolled section has a sharp tapered cross-section, so there is no need to forge it, but it can be made by simple pressing, working, and bending. |

| Hand-forged sickles are imbalanced due to the non-uniformity of the section, leading to a non-uniform moment of inertia. This results in uneven wear on the sickle blade. Also causes more fatigue for the user | Due to the uniformity of the taper section, the sickle blade has a uniform moment of inertia, which reduces fatigue for the user. The wear to the blade is uniform along the edge. |

| The sickle blade needs re-sharpening very frequently. | Due to the taper section, the sickle blade is self-sharpening. |

| Hand-forged sickles cannot be made on a mass production scale to cater to the huge market demand. | Sickles from hot-rolled tapered profile sections can be produced on a mass-production basis. This helps in keeping production costs low while maintaining a high level of consistency in quality, thereby providing high ‘value for money’ to the user. |

2. Automotive

We have expertise in manufacturing hot-rolled

steel sections for various automotive applications, such as:

- Door hinges for cars.

- Pole shoe sections for starter motors and dynamos.

- Rectangular and trapezoidal sections for flywheel ring gears and starter ring gears, sections for lock rings, side rings, flanges and advance bands for wheel rims of trucks, buses and forklifts.

- Serrated angles for the steps of buses and trains.

- Special T sections for pass-way interconnection of buses and many others, as per customer specifications and drawings.

3. Construction

We manufacture hot-rolled sections for various architectural applications such as ornamental grills, hand railings, gratings, T sections for joining chequered plates, serrated Ts for staircases, etc.

The use of such sections for grills, railings, and gratings provides an edge over the conventional flats or squares that are used for fabricating these items. Certain standard shapes and sizes are in our regular production range, but we can also manufacture and supply any other sections as per your drawings.

The pre-cast structures used in the construction industry are made off-site by using suitable molds. We manufacture two types of hot-rolled sections for use in pre-cast molds. One of the sections is an isosceles triangle that is available in different sizes and is called a chamfer. These chamfers are fitted into the corners of the molds of the pre-cast structures to obtain a chamfered edge along the length of the pre-cast column or beam. On account of such chamfered edges (no corner), corner breakage does not arise.

The standard sizes of chamfers (triangles) being supplied by us are 10×10, 12×12, 15×15, and 20×20 mm, but the same can be supplied in other sizes and specifications.

Another section that is used in the pre-cast molds and is manufactured by us is called a half-oval section. This section is used to obtain flutes on decorative pillars and is available in the required dimensions.

4. Cutting Tools

Hot-rolled sections are supplied for various cutting tool applications, such as cutting tool shanks, chisels, rasps, and planers for wood crafting and sections for engineers’ steel files and rasps.

We can also manufacture hot-rolled pre-shapes that can be cold-drawn to the blade sections required for clicking knives and leather-cutting

knives

5. Earthmoving

Grouser bars and lug bars for rebuilding track shoes. Dozers and excavators have tracked chains for moving in all kinds of difficult terrain.

The track chains or grouser chains are made of several track shoes or plates that form part of the undercarriage and get worn out during use. The chains have a discard life ranging from 2000 to 4000 hours of operation. The complete replacement of these chains is very costly, and hence the chains are re-furbished, which consists of rebuilding the grouser tip and the mounting holes. The re-furbished track chain provides at least 50% of the life of the new one at an extremely low cost.

We can also supply a profile section called the grouser bar profile, which matches the original worn-out grousers, and a 45-degree chamfer is provided at the bottom to facilitate proper welding on the worn-out grouser.

We can supply grouser bars in various cross sections suitable for various dozers and excavators in 3 to 5.8-meter lengths.

6. Horsehoe

Tamed horses have traditionally worn metallic shoes to protect their hoofs from injury due to exposure to hard, rocky terrain or modern roads.

Conventionally, horseshoes are manufactured by village smiths by hand-forging steel bars. This process of manufacturing horseshoes is very tedious and left to the skill of the smith.

In today’s modern-day life, where horses are used more for races than for transportation, shoe changing is very frequent, and the requirement is very large. It is therefore difficult for the village smiths to cater to such a huge demand, and this leads to the development of a modern process for manufacturing horseshoes on a mass production basis. To cater to the requirements of such modern horseshoe manufacturers, the profiles division has developed hot-rolled sections of various shapes and sizes that are suitable for manufacturing horseshoes suitable for various terrains, geographic locations, climatic conditions, and the nature of the work of the horses.

These hot-rolled sections for horseshoes can be supplied in bar lengths varying from 3 to 5 meters, as per your

specifications and section drawings.

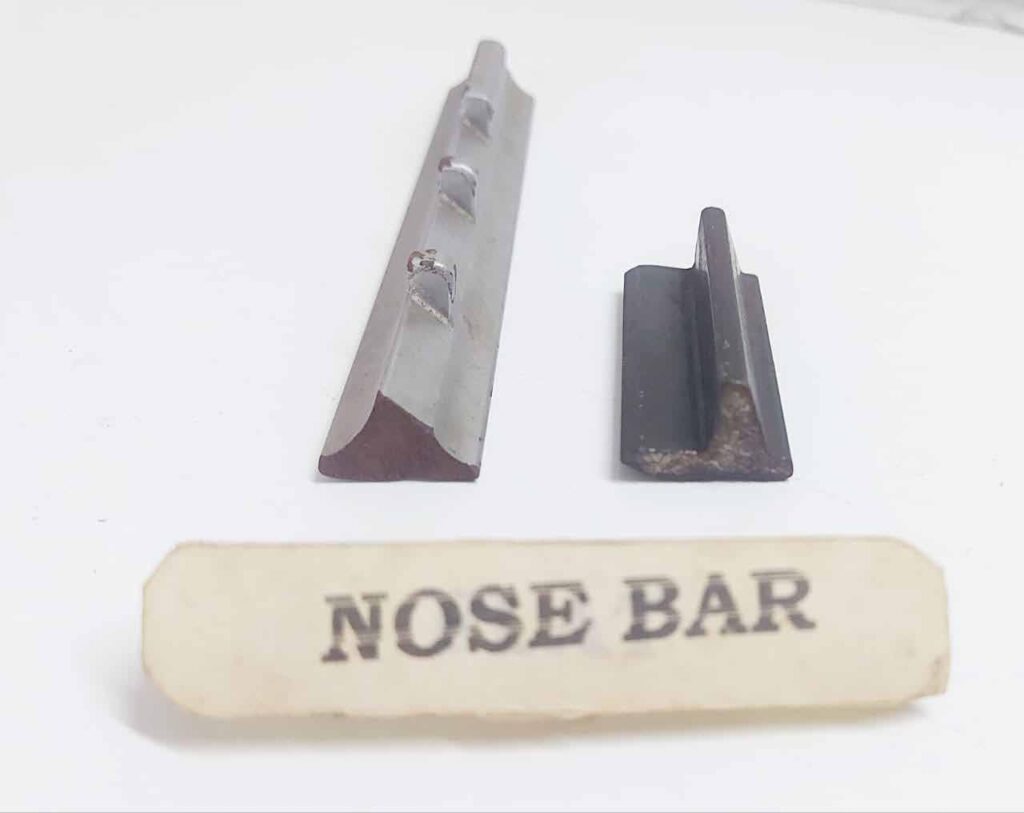

7. Textile Machinery

We cater to the requirements of several solid steel profile sections for textile machinery manufacturers, as listed below:

- Nose bar or apron bar for ring frame machines

- Condensor support bar

- Lappet rail

- Balance weight

- D bars

- Rod-weighing bars

MISCELLANEOUS

- Springs

- Taper washers

- Locks and keys

- Sliding rails for partitions

- Gibson ring and retaining rings

- Ratched Paul for pneumatic concrete breakers

- D sections for two-wheeler kicks and gear shifters

- Unequal angles with square edges for the tops of steel tables

- Knife-edge and bearing sections for mechanical weighing machines and many others, as per customer specifications and drawings.

We can also manufacture hot-rolled pre-shapes for further cold drawing or machining for various end products and applications, such as:

- Ratched Paul for pneumatic concrete breakers

- Machine tool guideways

- Linear motion guides ways

- Steam turbine blades

- Gear shifting and sliding keys

- Bearing steel flats

- Sections for sprays

- Half-round pipe casing used in oil exploration and any other pre-shape as per the customer's specifications and drawings.